Makeup production in the cosmetics industry combines science, creativity, and precision, working together to craft high-quality skincare and Makeup products. From conceptualizing innovative formulas to delivering the final product, every step demands meticulous attention to detail to ensure safety, consistency, and superior performance.

This article offers an in-depth exploration of makeup production, the diverse types of makeup, common production challenges, and proven best practices for maintaining quality and consistency.

Whether you’re intrigued by the journey of your favorite lipstick or curious about the rigorous systems that ensure its excellence, this guide unveils the intricate world of Makeup Production.

Disclaimer: “The images used in this article are AI-generated.”

Types of Makeup

- All-Natural Makeup: Made without synthetic chemicals or artificial ingredients, focusing on plant-based or mineral components.

- Vegan Makeup: It is created without animal-derived ingredients, making it cruelty-free and suitable for vegan lifestyles.

What the Manufacturing Process of Cosmetics Looks Like

The process of making cosmetics includes several key steps. It begins with creating a formula, followed by sourcing high-quality ingredients, carefully mixing them, monitoring production to prevent errors, and conducting thorough testing to ensure the final product is safe and effective.

At each stage of the process, there are chances for things to go wrong. This is why it’s essential to have checks and balances at every step to ensure everything stays on track.

Step-by-Step Process of Makeup Production

Product Briefing

The makeup production process starts when the customer communicates their needs to the manufacturer. They specify the type of product they want, such as a moisturizing anti-aging cream, a long-lasting lipstick, or 100% natural bridal makeup. This step ensures the product aligns with the customer’s vision and target market.

Formulation Development

Cosmetic chemists and formulators develop a formula tailored to the customer’s requirements. They carefully select ingredients such as pigments for color, emollients for smoothness, emulsifiers to blend oil and water, and preservatives to maintain freshness. The formula is designed to achieve specific goals like skin compatibility, durability, or desired texture while ensuring all components are safe and effective.

Ingredient Sourcing

The purchasing team secures high-quality ingredients from trusted suppliers. For example, they may acquire cosmetic-grade titanium dioxide for pigments or hyaluronic acid with the ideal purity and molecular weight for effective hydration. This step ensures the raw materials meet safety and performance standards.

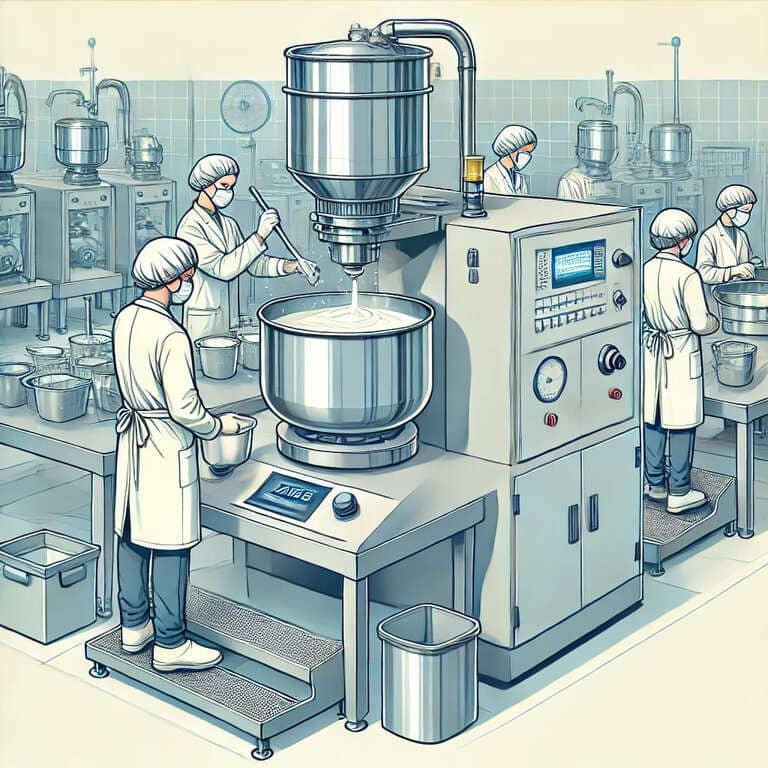

Batching and Mixing

Ingredients are weighed and combined in large industrial mixers based on the formula. The process of makeup production begins by creating a base with elements like water, oils, and silicones. Pigments and other active ingredients are then blended in, with careful attention to mixing speed, temperature, and time to achieve a uniform, high-quality product without over-processing.

Pre-Production Batch

A test batch is produced to verify consistency. Quality control teams monitor the batch, checking that the color matches the desired shade, the texture is smooth, and the viscosity is just right. If the mixture is too thick, thin, or inconsistent, adjustments are made before proceeding to full production.

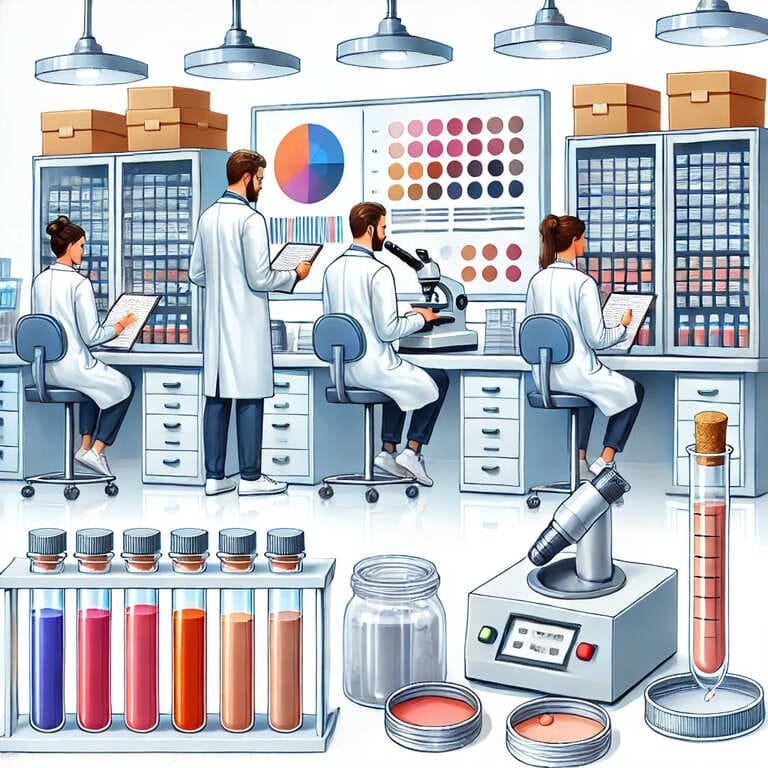

Quality Testing

Samples from the batch are sent to an in-house lab for testing. These tests include:

- Viscosity testing to ensure the product flows properly.

- pH testing to confirm it’s safe for the skin.

- Stability testing to check how the product holds up under varying conditions, such as high heat or freezing temperatures.

Filling and Packaging

Once the batch passes all quality tests, it is transferred to a sterile filling line. The product is filled into containers, such as bottles, jars, or tubes, ensuring hygiene and accuracy. Labels are added to provide essential information like the product name, shade, ingredients, batch number, and expiration date.

Final Quality Control

Before the products are released, random samples are inspected to confirm the packaging process didn’t affect the product’s quality. This final check ensures the product inside is consistent and meets all specifications.

Distribution

Approved products are carefully packed into shipping cartons and distributed to retailers, warehouses, or directly to customers. The distribution process is managed to protect the products from extreme temperatures or damage during transit, preserving their quality until they reach their destination.

What Are Some Examples of Mistakes During Makeup Production Manufacturing?

The manufacturing of cosmetic products is a detailed and complex process, and mistakes can happen at various stages. Below are some of the most common mistakes that can occur during the production process.

- Product Briefing Mistakes: One common mistake is when a customer requests a product concept that does not comply with current regulations. This can lead to legal issues and delays in the development process, requiring significant adjustments to meet the necessary standards.

Formulation Development Mistakes: Errors in calculations or measurements during formulation can result in a product that underperforms. For instance, the product might fail to provide adequate coverage, or the shade may not match the intended skin tones, affecting its effectiveness and appeal.

- Ingredient Sourcing Mistakes: Poor handling or sourcing of ingredients from unreliable suppliers can compromise the quality of raw materials. This can directly impact the safety, stability, and overall performance of the final product, leading to customer dissatisfaction or safety concerns.

- Batching and Mixing Mistakes: If ingredients are not mixed properly or added in the wrong sequence, the result can be an inconsistent product. This may cause issues like uneven color, separation, or instability, which affect the product’s texture and overall appearance.

- Production Oversight Mistakes: Failing to notice production issues, such as changes in viscosity or color, can lead to batches that do not meet the established specifications. These overlooked mistakes can result in a product that differs from what was originally intended, affecting its marketability.

- Quality Testing Mistakes: Inadequate or improperly executed testing can fail to identify defects in the product. Problems such as contamination, incorrect pH levels, or improper pigment dispersion might go unnoticed, leading to skin irritation or poor product performance.

- Filling and Packaging Mistakes: Malfunctions in filling equipment can cause bottles to be under or over-filled, while packaging errors may result in leaks or contamination. These mistakes can compromise the integrity of the product, making it unsafe or unattractive for consumers.

- Final Quality Control Mistakes: If quality control sampling is not representative, or if tests are not properly conducted, defective products can slip through the cracks. These overlooked issues might lead to subpar products reaching consumers, damaging the brand’s reputation.

- Distribution Mistakes: Improper storage conditions during shipping, such as exposure to extreme temperatures, can damage the product’s quality. For example, foundation products may separate, change consistency, or degrade in performance before they even reach the customer, negatively impacting the consumer experience.

Factors Affecting Quality and Consistency

Now that you understand the basics of how cosmetics are made and what could go wrong,

Let’s explore the main factors that affect product quality and consistency. The product depends on the ingredients used. Choosing reliable suppliers is crucial, as is Ingredient Sourcing and Quality. The final quality of a cosmetic is testing the ingredients before using them in production.

It’s also important to check the packaging carefully. Sometimes, beautiful products are ruined by poor packaging, which can cause them to be discarded.

Equipment and Facilities

The equipment and facilities used in production are key to ensuring consistency and quality. Machines like filling devices and measuring tools must be precise. The cleanliness of the facility also matters. Air vents, pipes, and other equipment used to transport ingredients must be cleaned regularly to prevent contamination and ensure the product is safe.

Regulatory Compliance and Standards

The cosmetics industry has strict regulations to ensure safety. Manufacturers must follow these rules to make sure their products are safe for consumers. These regulations may vary by region and may include specific customer requirements that must be met.

Testing and Analysis Techniques

To ensure a product’s quality, various tests are conducted. These tests check that the product is safe and effective throughout its entire life cycle. It’s important to choose the right tests for each product to avoid safety issues and ensure high-quality results.

Best Practices for Ensuring Quality and Consistency of Makeup Production

So, how can these practices be effectively implemented? To consistently maintain high-quality cosmetics, companies should focus on the following essential steps:

- Use Good Manufacturing Practices (GMP): Good Manufacturing Practices (GMP) provide guidelines that cover every aspect of production. These guidelines help prevent contamination and reduce errors in the manufacturing process. Companies often follow ISO standards, such as ISO 22716:2017, or equivalent standards to consistently produce high-quality products.

- Implement a Robust Ingredient Testing Program: Teams thoroughly test every ingredient for quality before using it in production. They discard any ingredient that doesn’t meet specifications. Implementing a strict testing and rejection process for subpar ingredients ensures that only the best raw materials go into your products, maintaining high standards.

- Skin Consult’s Role: Skin Consult can assist in approving ingredients. Since ingredient evaluation is a key part of the safety assessment, Skin Consult helps ensure that every ingredient meets strict safety and quality standards before it’s used in production.

Proper Equipment Maintenance and Calibration

- Meet Regulatory Requirements: Staying up to date with industry regulations is essential. Companies must ensure their products comply with current regulations and meet safety standards to avoid legal issues and ensure customer trust.

- Skin Consult’s Role: Skin Consult’s experts are highly knowledgeable about the cosmetics industry, including both current regulations and upcoming changes. They guide companies to ensure compliance with both existing laws and new regulations in development.

Using Advanced Testing and Analysis Methods for Makeup Production

Advanced testing equipment allows for more precise and quicker results. Modern tools provide deeper insights into product quality, helping manufacturers maintain consistency and meet the highest standards.

- Skin Consult’s Roll: Skin Consult can provide expert guidance on using advanced testing methods. They help ensure that testing procedures are effective and that products comply with industry standards, contributing to the overall safety and quality of the final product.

How to Maintain Quality and Consistency for Cosmetics Manufacturers

Maintaining quality and consistency in cosmetics manufacturing is an ongoing process that requires dedication, proactive planning, and a company-wide commitment.

Here’s how manufacturers can achieve and sustain high standards:

Provide Regular Employee Training for Makeup Production

Continuous training is essential to ensure employees understand and implement the latest quality standards and best practices. Regular sessions help keep staff informed about new industry trends, quality control procedures, and safety regulations. Well-trained employees are the foundation of a reliable and consistent production process.

Continuously Review and Improve makeup Production Processes.

Take a Proactive Approach to Problem Prevention in makeup production.

Don’t wait for problems to arise focus on preventing them before they happen. Implement risk management principles to identify potential vulnerabilities, such as supply chain disruptions or safety hazards in the factory. Develop strategies to address these risks, such as backup plans for material shortages or regular equipment maintenance to prevent malfunctions.

Cultivate a Strong Culture of Quality

Quality should be a shared value across the organization, not limited to a specific team or department. Foster a mindset where every employee, regardless of their role, prioritizes quality and safety. When quality becomes a core value embraced by everyone, it creates a consistent and reliable production environment.

Encourage Open Communication

Build an environment where employees feel comfortable sharing concerns, suggesting improvements, and reporting potential issues. Transparent communication helps address problems early and implement solutions effectively.

Quality Management System for Makeup Production

A detailed quality management system (QMS) is crucial for maintaining high standards and ensuring consistent processes in cosmetics manufacturing. A strong QMS helps track operations, improve product quality, and maintain compliance with industry regulations.

Here are some key elements of a Robust QMS:

Comprehensive and Documented System

A well-structured QMS should cover every aspect of the manufacturing process, from sourcing raw materials to the final product. Documenting these processes ensures transparency and consistency. Regular audits, preferably by external partners, help identify areas for improvement.

Industry Standards and Certifications

Certifications like ISO 22716 (Good Manufacturing Practices for Cosmetics) and ISO 9001 (Quality Management Systems) are benchmarks for quality and safety.

- ISO 22716 focuses specifically on cosmetics manufacturing, providing guidelines to ensure safe and high-quality products.

- ISO 9001, Though broader, emphasizes overall quality management, and organizations, including service providers like Skin Consult, can apply it, showcasing their commitment to safety and quality.

Attention to Manufacturing Processes

Producing safe and high-quality cosmetics requires careful attention to:

- Choosing the best raw materials from trusted suppliers.

- Maintaining equipment to prevent contamination or inconsistencies.

- Adhering strictly to industry regulations and standards.

Regular Testing and Analysis in Makeup Production

Routine testing ensures that products meet safety, efficacy, and quality standards. Analysis of raw materials, in-process batches, and finished products helps maintain consistency and identify potential issues early.

People-Centered Approach

Conclusion

Producing high-quality makeup is a complex and multifaceted process requiring expertise, precision, and a commitment to safety and quality. From sourcing the finest ingredients to implementing rigorous quality management systems, every step plays a crucial role in delivering products that meet customer expectations. By adhering to best practices, fostering a culture of quality, and utilizing industry standards like ISO certifications, manufacturers can ensure their products remain consistent, safe, and effective.